BHJProducts.com - High Performance Engine Builder Tooling and Harmonic Dampers

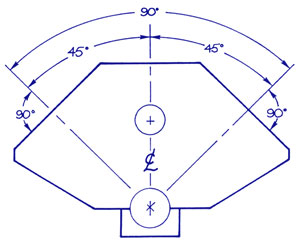

BHJ's Blok-Tru engine block blueprinting fixture corrects improperly machined deck surfaces, commonly caused by factory machine tolerances and production line inaccuracies. This precision-machined fixture has a true 45-degree angle machined at each side of its own centerline.

The Blok-Tru Index Plate, when installed on the cam-crank centerline of the block, is then referenced to roll over and correctly index the block into position for the resurfacing operation (bottom photo). An optional upgrade allows the Blok-Tru to also work with Ford's Triton/Modular blocks, which lack a cam tunnel by design. Click here for the Blok-Tru Basic Kit for more.

When the Blok-Tru is set-up and used in the prescribed manner, all angular dimensions shown in the illustration above can be held within five minutes of one degree. Top engine builders across the country rely on the Blok-Tru to provide the level of accuracy necessary for today's performance applications.

The Blok-Tru can be tailored to fit virtually all automotive resurfacing machines, as well as conventional vertical and horizontal milling machines. The Blok-Tru is offered in Kit form to fit several of the more popular resurfacers, or can be put together with the individual components necessary to suit your application. See the Blok-Tru menu page for specific kits and associated support parts.

Click here for a customer's Blok-Tru theory and setup procedure video (YouTube)...

Click here for a customer's Blok-Tru purpose and use video (YouTube)...

Click here to see the Blok-Tru at work, in the Chevy Hardcore Blueprint Series story: Measuring & Setting Deck Height & Finish (Chevy Hardcore)...

Common issues improved after using the Blok-Tru include: